Part # B625

Warranty 1 Year

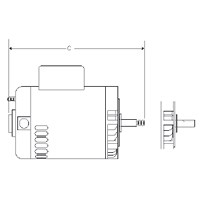

Uprated 3/4 HP motor; 3450 rpm, 208-230/115; 8.5-7.8/15.6 full load amps; 1.5 service factor; 56CZ frame

Most commonly used on Polaris Booster Pumps

What is Service Factor?

Reply

Service Factor(SF) is a multiplier that when multiplied by the horsepower of the motor indicates the total permissible horsepower loading that may be carried when the motor is operating at rated voltage and frequency. The most important thing to remember when replacing a motor is that the replacement motor's horsepower times its service factor must be equal to or greater than the original motor's horsepower times its service factor. The Service Factor rating can be found on the motor label. See Step 4 of our How to Read a Pool Motor Label guide.

Reply

Why do I need to purchase a new shaft seal?

Reply

We strongly recommend replacing the shaft seal. The purpose of a shaft seal is to prevent water from running down the shaft of the motor and into the motor housing. Water will damage the bearings and cause the motor to fail. A new shaft seal should be installed whenever a motor is replaced. The motor manufacturer can deny the warranty if the motor fails to due to water damage from a faulty shaft seal. To find your shaft seal you will need to visit our Pool Pump Parts Page or the Spa Pump Parts Page and select your make and model.

Reply

Why should I purchase a Tune Up Kit?

Reply

A Tune Up Kit includes all of the essential replacement seals and gaskets for the pump. The seals and gaskets should be replaced when installing a new motor on your pump. New seals will prevent the pump from leaking water or losing the prime. A Tune Up Kit will protect your motor and ensure that the pump is working efficiently.

Reply

I have a polaris pump ao smith part o-173840-23. It recentlt started a high pitch scream. Bearings ?? Something that can be easily replaced?

thanks

Reply

Hi William, You can replace the bearings of your Polaris booster pump motor. You will need (2) A.O. Smith 203 Bearing (6203RS). We have How To Replace the Bearings in a Pool Pump Motor - Part I, How To Replace the Bearings in a Pool Pump Motor - Part II to assist you in replacing the bearings in your motor.

Reply

Less than 1 hr

Screwdriver, Nut Drivers, Wrench Set, Rags and mild cleaning chemicals

1 0

I watched the video for this repair that inyo pools produced for guidance. I first cut power at the breaker. Then I disconnected the boost pump from the inlet and outlet hoses. I removed the electrical access plate from the back of the motor and disconnected the wiring, being mindful to take a photo prior to disconnecting. Then I carried the assembly over to a table and removed the impeller cover. I then removed the shaft cover and used a wrench to hold the shaft in place while I spun the impeller off by hand. I then removed the shaft seals and the aft impeller housing and was only left with the motor, which I discarded. Assembly was opposite of disassembly, but I purchased all new shaft and housing seals. Nothing worse than fixing something and then having to take it apart a month later because the old $5 seal failed. I hooked everything back up, turned the power on at the breaker and gave the system a test. The impeller sounded very loud, but I had the vacuum disconnected. Once I attached the vacuum to the wall outlet and the system got some back pressure load on it, the noise stopped and everything was working like new.

The Most Helpful Review

1 1

(5 out of 5 stars) Polaris pump

Reviewed By: Franklin B. H. from Beaumont, Tx. ()

Pump works great, same pump sold at pool stores for a much cheaper price.

Was this review helpful to you?

The Most Recent Reviews

(5 out of 5 stars)

Reviewed By: Inyo Customer ()

Perfect replacement. Great help from customer service.

Was this review helpful to you?

(5 out of 5 stars)

Reviewed By: Inyo Customer ()

Perfect replacement

Was this review helpful to you?

(5 out of 5 stars)

Reviewed By: Inyo Customer ()

great service. correct oem part., not off brand replacement.i was surprised it showed up so fast. Will continue to order parts from them.

Was this review helpful to you?

(5 out of 5 stars) As expected

Reviewed By: Inyo Customer ()

Exact replacement for Polaris vacuum motor. Easy instal. Does not come with shaft O ring (11/16") OD, which will likely need to be replaced.

Was this review helpful to you?

(5 out of 5 stars) Easy

Reviewed By: William P. from Lakewood, IL ()

Pros: Ease of installation

Cons: none

No surprises. Easy to install. Works perfectly. Quiet.

Was this review helpful to you?

(5 out of 5 stars) Easy replacement with the identical same motor.

Reviewed By: Buddy from Fort Worth, TX ()

INYO gave free delivery for the booster pump. The booster pump arrived before the anticipated delivery date. The pump is the identical pump which I was replacing. This made for an easy replacement. I would recommend INYO to my friends and family. I will definitely use INYO Pools in the future.

Was this review helpful to you?

1 0

(5 out of 5 stars) Booster Motor

Reviewed By: Peter Adelfio Sr. from Mooresville, NC. ()

This motor was delivered quickly. The installation was simple and it is running perfectly. Inyo pools has all your pool needs right from the comfort of your own home.

Was this review helpful to you?