The PureLine Prime Pump is one of our newest, premiere pumps that rivals top brands like Hayward and Pentair. The PureLine Prime is paired with A.O Smith’s 2 Green premium efficiency motor which has an integrated timer that allows for a much smoother and simpler install. Since the motor is the only electrical component within the pump, it is typically the part that will sustain the most wear and tear. And with any moving part, you’re bound to run into some issues at one point.

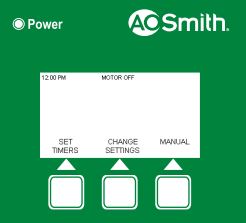

Century’s 2 Green integrated electronics control the power supply to the motor. The user is responsible for setting either the Timer Mode of Manual Mode to operate the pump. In short, the user has to program when they want the motor to start and stop High and Low speeds. If either setting has a user error, an error screen will appear and prompt immediate action. Between wear and tear and user error, there are a few things that pool owners can encounter along the way.

User errors are easily managed and can usually, but not always, be fixed by the homeowner themselves. Why spend money on something you can easily do yourself, right? One of the major benefits of the Pureline Prime Pump is the integrated timer. The majority of dual speed pumps do not come with an integrated timer. What that means is that in order to control when the motor would turn on and off, homeowners would have to purchase a separate timer and wire it to the motor. The integrated timer allows you to forgo that entire process

On the flip side, if there is an error on the timer, either user error or manufacturer’s defect, the entire motor is affected. The user has to address the error message in order for the motor to re-start. Exactly what type of error messages will you see, you ask? Let’s explore them and how to get rid of them

How Do I View The Error Log?

Electronic malfunctions may cause error codes to flash on the screen. If this happens, the timer will automatically disable. You will have to recycle the power. The timer stores the last ten (10) faults in a log that you can access and review. To view the log, follow these steps.

- Press CHANGE SETTINGS at the main screen.

- Press MORE MENU

- Press FAULT CODE

- Press UP or DOWN to scroll through the log. This screen will show the day and time the error occurred. Press HOME to return to the main screen.

Here are two examples of fault screens that may appear:

Once the error log is displayed, it will show you the Fault Name, Fault Code, and a short message that shows the course action to reset the fault.

The table below shows the various Fault codes that may occur

| Fault Name | Fault Code # | Course Action To Reset the Fault | Remarks |

|---|---|---|---|

| RAM Fault | 03 | Remove power or call a service person. | Wait for a minimum of 15 sec. and then take necessary action. |

| REGISTER Fault | 04 | Remove power or call service person. | Wait for a minimum of 15 sec. and then take necessary action. |

| CLOCK Fault | 05 | Remove power or call service person. | Wait for a minimum of 15 sec. and then take necessary action. |

| ADC STUCK Fault | 06 | Remove power or call a service person. | Wait for a minimum of 15 sec. and then take necessary action. |

| OVERCURRENT Fault | 07 | Remove power and rotate the shaft. | Wait for a minimum of 1 hr. and then take necessary action. It is due to the shaft locking. |

| EEPROM Fault | 08 | Remove power or call a service person. | Wait for a minimum of 15 sec. and then take necessary action. |

| EEPROM CONFIGURATION Fault | 09 | Remove power or call a service person. | Wait for a minimum of 15 sec. and then take necessary action. |

| RTC Fault | 10 | Remove power or call a service person. | Wait for a minimum of 15 sec. and then take necessary action. |

| KEYPAD Fault | 11 | Remove power or call a service person. | Wait for a minimum of 15 sec. and then take necessary action. |

| OVERLOAD Fault | 12 | Remove power and check the impeller size. | Wait for a minimum of 1 hr. and then take necessary action. IT is due to a motor overload. |

If you can’t discern what the issue is and how to fix it, never hesitate to reach out directly to Century Motors. Often times they can help troubleshoot your motor with you over the phone. Keep in mind, every 2 Green motor will come with a one year manufacturer’s warranty. The warranty also covers any defect that may occur on the timer as well.

Don’t forget, you can also submit questions to us at upload@inyopools.com.

I have a Century Two Speed AO Smith B2982T Pool Motor.

The keypad doesn’t work and I am getting “FAULT 11 KEYPAD FAULT” which resets if you cycle the power.

Are there repair part available for this motor?

Thanks,

Bob Christensen

Englewood FL

flyboy.bob@gmail.com

Bob; did you ever get a response to correct this fault??

I have had 2 over the past 4 years. Display gone on both renders them useless.

Hi Brian I have a V green century variable speed motor and a pentair ultra flow pump.

When I turn on motor it just jams and the fault light comes on.

When I look at motor from the rear it is spinning clockwise which is the way it locks. If I were to turn it anti clockwise is just spins fine. Any suggestions?

I have two errors with the Century A.O. Smith B2984T Premium Efficiency Dual Speed Pool Motor.

I have had it two years and today it now stopped and shows me

Error #1 = Fault 7 Over Current Fault Remove Power and Rotate Shaft. and

Error #2 = Fault 12 Overload Fault Remove Power and Check Impeller.

It works ONLY on SLOW speed but locks up on high speed.

Question: You think I should replace the pump Impeller before replacing the motor?

Hi, were you able to fix the errors in your pool motor? I have the exact pool motor that I bought from Inyopools. I had it for 1 1/2 years and got error message “Fault 7…” few days ago. So I searched the interned and found this thread.

I removed the motor, rotate the shaft and even changed the shaft seal but still it shows the same error message even if I try to turn it on on slow speed. I removed the motor 2 times and even lubricated the shaft but same thing. I hope somebody from inyopools give us some instructions on how to fix the error message.

Any luck with this repair?

I have a century 2 stage (2 Green ) motor and get “Error 7 ” only in the low speed stage and NOT the high speed stage. Is this a different problem than just an error 7?

Fault &

The article mentions Overcurrent as the issue for error message 7. The suggested next step is as follows:

A locking shaft could be an issue with bad bearings. Is your motor making any loud grinding noises? The rusty bearings create extra friction; that extra drag is too much for the motor to turn on low speed.

I have same proble. did you find a fix?

Any comments on reliability on these motors? No serviceable parts on the controller, toss entire unit when it fails…

Reliability for the 2Green and the standard dual speed motors without a timer are pretty much the same. The two motors use the same vented induction motor which is susceptible to heat or anything that can find its way into its vent holes.

If you want a motor that lasts longer than these, I suggest the V-Green Variable Speed. Read our blogs about them here: Century’s New V-Green Pool and Spa Motors: Part I Part 2