A question that popped up a bunch when I began in the pool business was “if I use 230 voltage will it save me money?” To be honest, I thought I knew the answer and that hubris made me look like a fool my first day. But after a little research I quickly found the knowledge and now it’s time for you to be let in on this secret.

The Confusing Part

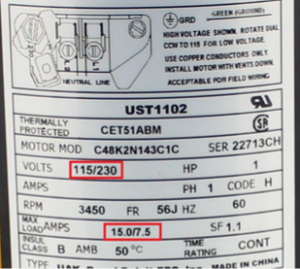

Look at a dual voltage (runs on either 230 or 115 volts) pump motor and read the ratings. In our example the volts read 115/230 and the amps are to be read respectively. That means on 115 volts the motor draws 15 amps and on 230 it uses 7.5 amps.

My first and admittedly ignorant understanding was that the power consumption/cost was linked solely to amp usage. That led me to believe that 230 was naturally more energy efficient than 115. After all it uses half the amps, but not so fast Mr. Jump-to-Conclusions – that is wrong. Power bills use Kilowatts Per Hour as their unit of measurement. And the formula to figure out watts usage requires both voltage and amperage.

Watts Formula: Watts = Volts x Amps

120V x 15A = 1800 Watts

compare to

240V x 7.5A = 1800 Watt

Kilowatts Per Hour Formula: Watts x Hours Run ÷ 1000

1,800 Watts x 10 Hours ÷ 1000 = 18 kWh

The watt usage is virtually identical when calculated in this manner. Part of the reason watts is the same is because of the way the two voltages are wired. The amp rating shows the usage per “hot” wire, also called load-bearing wire. A 115 volt circuit is wired with one hot wire that carries the current with one neutral and a ground wire; while 230 volt circuits are wired with two hot wires and a ground. The amp load is split between the two hot wires which provides the somewhat deceptive amp draw on the motor label.

But Why Use 230V Instead of 115V?

Most major countries outside of the US (especially in Europe) utilize 230 voltage for their electric grid while the US uses 115 as our standard. Early development of the US electric grid took place before most of the world, and coincided with a period during which light bulbs and appliances were very susceptible to failure due to high voltage. This made the American power companies install and standardize the 115 volt power stations we see today. By the time Europe was building its electrical infrastructure, most of the kinks had been worked out for bulbs and electrical components to safely run on high voltage. This was perfect timing as 230 voltage is a more efficient way of conveying electricity over long distances.

Most houses in the US still have access to 230 volts as you may have noticed when installing heavy duty appliances such as a washer and dryer or electric range. In the pool industry, pool motors with a horsepower output of two or above almost always are 230 volt hook up only. This is because with high voltage comes great amperage.

When we flick the switch on a monster of a 3 HP motor, that mechanism demands amps to be able to fire the capacitor, switches and windings. If there is a delay in amps reaching the motor, it may cause the motor to overwork and overheat to compensate. This extra work put in by the motor means it is more likely to fail earlier than it should.

Think of it as if we were sipping a thick milkshake but all we have is a thin straw. When you begin to sip on the straw no matter how hard you try, you will go red and eventually quit with your thirst not quenched. That is essentially what happens to a big motor using 115 volts. It’s got a fever, and the only prescription is more amps. Now switch that tiny straw with a hefty wide straw, your work load lessens, you’re cool as the other side of the pillow. Voltage is the straw, and the amps are the milkshake. Voltage is just there to help convey the amps to the unit.

Wow lots of opinions for both scenarios . I want to change my 1hp to 230 from 115 but this thread has made me go…. ummmmm? I feel the general consensus is, that if you have the option to easily switch to 230…..then do it correct? Would everyone agree? Looking forward to the continued opinions ! Thanks for the help everyone !

If I can put in my vote, I would prefer 230 volts over 115.

I have Hayward 1/2 hp 230/115 new replacement motor

I have a three wire set – black, white & green

In the panel a 20amp breaker

Which do I use ?? The 115 or the 230 🤔

If the color coding is correct, the black and white wires means it is a 115-volt circuit.

From what I understand is the motor works better, more efficient. It will do the job better and last longer. Better torque say for an air compressor.

You were right the first time, but not for the reason you thought. Running a motor on 230 volts is more efficient than running the same motor with the same wiring on 115 volts. The reason is not because the motor itself draws any less power, because as you observed, the wattage is the same. The chief difference is the amount of current drawn is cut in half when you double the voltage. Most pool pumps are connected using 12 gauge wire, which is rated for up to 20 amps. The reason there is a current limit is because as you increase the current, the wire heats up more. As it heats up, it increases its resistance, and so the motor will draw even more current to compensate, which causes more heating, and also causes your motor to heat up more, and shortens the life of the motor. Even if you only draw 15 amps at 115 volts, your wire will heat up more than if you draw 7.5 amps, and so you will be wasting energy by heating up your supply wires. Raise the voltage, cut the current, save energy, increase the life of your pump motor, and SAVE MONEY.

Whether in North America or Europe, the electric grid does not run on 115 or 230 volts, it runs on much higher voltages. For instance, in North America, power on the grid is typically sent over transmission lines at voltages ranging from 69 to 765 THOUSAND volts. Closer to where it is used, there are substations which lower the voltage to typically 7,200 to 14,400 volts (single phase) for local distribution. Within a few hundred feet of your house, the voltage is reduced to 230/115 volts. The main difference between Europe and North America is that in Europe, the power is typically distributed to buildings at only 230 volts over 2 wires, whereas in N. America it is distributed at both 115 and 230 volts over 3 wires. While it is true that 230 volts is more efficient over long distances, at that voltage the distances involved are generally only a few hundred feet, the distance from the transformer to the building. It has nothing to do with the grid, which spans hundreds or thousands of miles.

What happens when you run 115 but the back of the pump is switched to 230.

Check the motor label. If the label says it is a dual voltage 115/230 then you would switch the motor to 115, and follow the wiring directions. If it is a 230 only, then you need to buy a different motor or set your circuit up for 230.

I have a leisure spa with a 3 hp pump at 115/230 volt. Amperage at 115 volts says 16.6. amps At 230 volts 8.8 amps. What happens is it is drawing 24 to 28 amps at 115 volts with a load. Installed new wet end and seals per XPS motor and pump. It blew the circuit relay way before I put new wet end on. Soldered new relay and works again. However amperage still high and don’t want to ruin relay again. Pumps and starts like crazy. Start cap checks fine. Is it possible the run and start are engaged due to the centrifugal relay inside the motor. I checked springs and contacts look clean. The mechanism you hear engaging when you start the motor. And disengages when you turn it off. Motor turns free and no noise. It will get hot and voltage has always been wired for 115 volts. I am leaning toward maybe running on start winding only. Unless centrifugal switch has an issue. Or unless both winding’s are running together. Don’t want to burn relay on board again. Winding seem to bright colored no signs of water in motor. Inside. I removed the stater and checked all the connections and start switch and start cap.Starting to think this motor has always run borderline. All the jets and returns are wide open as well.

Hello Tim – I reached out for some help from Century and their senior tech replied with the below response:

Can you provide the requested info?

Thanks, Matthew, for the great explanation. clarified everything tremendously!

Excellent topic. This great article must help the air compressor users.

Thanks

I recently changed out to a new pump that has both 115/230 options. The previous was 115 but before that I had a 230 (therefore I do have the wiring option in the box where the pump wires in).

I have found that the new pump is running hot in temperature and cutting out. I took the end cap off and ran it all day with no problem, put it back on and it overheats and cuts out.

Would using 230v produce less internal heat?

Have you checked to make sure the lines are putting out the correct voltage? Also, are you making sure you are switching the voltage knob on the back of the motor?

Great info. I am looking at buying a house that has an indoor inground pool. My HVAC guy told me it’s wired for 115 which bothered me, but after reading this I’m much more comfortable. I did not look at the HP when we were there but it’s smaller than the one I have at my current house which is 1.5 HP. Thanks!

Glad to help!

Thanks Matthew, really great info.

Can i use a small motor from the USA in Estonia?

the motor is a follows:

H.P.: 1/4

Volts: 115

Phase: 1

Amps: 3.0

Cycle: 60

R.P.M.: 1725

The house i will be at has 230 volt 3 phase power.

The size of the pump needed is determined by the size of the pool and chlorine needs. Unfortunately, I do not know the pool regulations for any former Soviet Bloc countries, but if I were you, I’d check with the home inspectors in your area of Estonia.

In Estonia like you said has all the wires for 220 or 230. You need a power reducer and plug

There is a savings in the size of the wire you have to buy using 230 instead of 120

for higher loads & variations in demand 230v is alway the more cost effective . the wattage total per /hr will end up less . the 230 circuit is 7.5 A ; but that does not imply that it demand 7.5A all that running time . thanks for the info Matthew ,that was very good .

very good explanation Matthew ! the other way i’ve looked at it is that both wattages are the same but which motor has to work harder under load variations . the 230 is always more cost effective . kinda relates to a 4cyl engine vs 6cyl . the 4 does better on level roads until hills & head winds are encountered , then it’s changes everything . thanks for the info .

In an example of a 115 motor that pulls 10 amps and a 230 that pulls 5 amps….the 230 pulls 5 amps on 2 hot legs….is that really 10 amps?….since we are using both sides of the breaker panel?

Your power company charges are based on kilowatts; the way you figure out kilowatt usage is by multiplying volts times amps.

115 V x 10 amps = 1,150 Watts = 1.15 kW

230 V x 5 amps = 1,150 Watts = 1.15kW

You’re missing a very big issue especially in regard to motor loads, capacitive and non capacitive.

First the initial draw ( especially with a pump full of water ) is the FLA rating and not necessarily the running amps.

Second when using 120vac the entire 15 FLA ( using your example) is taken off one leg of the power supply ( United States) , when splitting the load across both sides of the supply, the initial amperage draw will not load the service creating a much less voltage drop.

Just as I mentioned the voltage drop would be the last part your missing in your equation, with the load split between both sides of service, there will be little to no voltage drop, this is why all high amp draw appliances use 240vac, along with the wire size that would be needed to feed a 30A circuit with 120vac it’s not practical.

The meter that measures your power is an ampmeter, when the voltage is low the current ( amps) raise to compensate and your meter will measure this, erroneously raising your electric bill, not to mention things like your air conditioner, refrigerator, etc., do not like low voltage and will promote premature failure.

I’m not saying a single 15A 120vac load will create a voltage drop, but what if your A/C is running, your electric oven is cooking, and your fridge kicks on.

Late to the game, I know. But I have worked for power companies my entire 33 year career and I’m afraid your understanding of motor ratings, electric meters, and billing is not quite accurate.

Revenue meters are watt-hour meters, not ammeters; most modern meters are electronic and read watt-hours and watts (spinning-dial mechanical meters in the past measured only watt-hours). Regardless, the meters use actual voltage and actual current to arrive at the kilowatt demand (if your rate includes demand charges) and kilowatt-hour energy usage.

There is no significant difference, financially, in having your pump on 230V or 115V; your rates are based upon demand and energy (combining voltage and amperage), not amps, alone (generally wiring losses from heating will be less at 230, but likely not to a level that would be noticed on your bill).

Energy is a measure of how much work gets done, and power is the speed at which energy is used. If you do all your work in one hour instead of, say, four hours, the same amount of work gets done (energy — kWh — is the same); however, the demand (power — kW) is four times higher. Higher demand = bigger equipment needed = possibly higher costs (depending upon your power company’s rate structure).

The Full Load Amp rating of a motor is the steady-state amp draw when the motor runs at full output, not the starting current of the motor. The LRA (Locked-Rotor Amperage) is the starting value. At the instant a motor is powered, the rotor is not turning (the same situation electrically as when the rotor is “locked”) and the motor draws its highest amperage, decreasing as the rotor attains its nominal speed.

The temporary “inrush” of current does drop the voltage (maybe noticeable, maybe not, depending upon many factors — wire sizes and lengths, transformer sizing and loading, primarily); however, that has no effect on the meter or on your electric bill. It can, indeed, affect other equipment if the drop is high enough. Most electrical equipment, however, is designed to withstand voltage variations of +/- 10%.

Not enough practical benefit, IMO, to convert from 115V to 230V if you’re not making other changes already. If you’re changing pumps or wiring, anyway, it wouldn’t likely be a mistake to make the change.