No one likes to get an error code on any piece of technology, especially on a Raypak heater. It means something is wrong and needs to be addressed soon. The panic really doesn’t set in until you realize error code BD1 means absolutely nothing to you. Error codes are both curses and blessings. Although an error message is never really a good thing, at least it’s an indication of what the problem is. Just imagine how much easier it would be to diagnose diseases if humans came with error codes.) Usually, depending upon the manufacturer, the manufacturer will include a manual detailing what may have triggered the error message and possible solutions to fix the issue. All error code guides are not made equal.

Still, even if the error codes were listed in the manual, what are the odds you know where that manual is? Unless you’re like my mom who keeps all her paperwork in a filing cabinet, the manual was probably tossed a week after your product was working properly. Heaters, though, can be rather tricky without the manual. I love the saying, “hindsight is 20/20,” because it’s so true. How many times did you wish you kept something after you have convinced yourself that you didn’t need it and threw it away? Or maybe it’s just me.

Our goal with this blog is to aid you in identifying and defining the error code on your Raypak heater and to provide possible solutions, as per the manufacturer. If we don’t have a solution or do not address your particular issue, it’s always best to contact Raypak directly.

The majority of Raypak heaters will have a digital readout. The digital readout helps pool owners read error codes on the actual heater. The models with digital thermostats are programmed to display a variety of status and diagnostic messages, depending on the operating conditions.

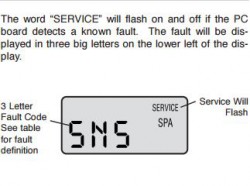

They are also equipped with onboard diagnostic controls. If there is a safety fault, a fault code will be displayed along with a service indication. (see pic on right) The word “SERVICE” will flash on and off if the PC board detects a known issue. The fault code is displayed in 3 big letters in the lower left of the display.

Below is a chart we created to help pool owners identify the meaning of Raypak’s fault code. It also includes possible solutions to fix the issue. Keep in mind, this is not a substitute for the installation and operation manual. Should you need further advice or technical information, please give Raypak a call at 805-278-5300.

| Fault Code Display | Definition | Possible Solutions |

|---|---|---|

| BD1 | Board failure | 1. If this code appears and stays on, turn off power to board at toggle switch and source, then re-establish power. 2. If code reappears, replace board as the main processor failed to start. |

| EEP | Indicates that memory failed to start on main processor. | 1. Turn off power at toggle switch and source, then re-establish power. 2. If code reappears, replace board as memory has failed. |

| FAN | Indicates the Pilot was lost, or the air pressure switch is not closed when required. | 1. Check for correct incoming power at fan relay- 120V or 240V and at fan motor. 2. If pilot is confirmed, check for 24V minimum out of fan relay to pressure switch. 3. If switch does not make when fan is operating, verify the tuning between fan housing and switch is connected and is not kinked. 4. Soft lock out after 3 attempts- automatically resets after 5 minutes. |

| FFL | Indicates a false flame signal. | 1. Check to see if pilot is staying lit after CFH is satisfied. If pilot stays lit, the pilot valve in the gas valve is hanging open. Replace gas valve. 2. If gas valve is working properly, problem lies with the pilot system or board. Turn power off at toggle switch. 3. Unplug ignition wire from board and pilot and remove green ground wire from burning tray. Clean and reconnect ground wire. 4. Turn power on. If no spark at ignition module, turn power off and replace the PC board. 4. If you saw a spark at Ignition Module, turn off the power and reconnect wires. 6. Turn power on and unit should fire. |

| GVC | No power detected at PV or MV when commanded. | 1. Turn power OFF and disconnect Ignition Wire and Gas Valve wires from board. 2. Power ON and watch for spark at module. 3. If no spark, turn power OFF, and replace board. 4. If spark is observed, turn off power and reconnect wires. The unit should fire. 5. If unit does not fire and code reappears, power OFF, disconnect valve wires from board and remove MV, PV, and ground wires. Clean and reconnect. 7. If unit does not fire, replace the gas valve. |

| GVO | Power found at either PV or MV at the incorrect time. | 1. Turn power OFF and disconnect Ignition Wire and Gas Valve wires from board. 2. Power ON and watch for spark at module. 3. If no spark, turn power OFF, and replace board. 4. If spark is observed, turn off power and reconnect wires. The unit should fire. 5. If unit does not fire and code reappears, power OFF, disconnect valve wires from board and remove MV, PV, and ground wires. Clean and reconnect. 7. If unit does not fire, replace the gas valve. 8. Low power to transformer can cause a GVO fault. |

| HL1 | The high-limit has exceeded 135F | 1. Possible excessive water temperature in the tube bundle. Once heater cools, high limits resets automatically. 2. Check for blockage in tubes. 3. Check for low water flow. 4. Check Unitherm governor- replace if necessary 5. check bypass assembly- replace spring or bypass if necessary |

| HL2 | The high-limit has exceeded 135F | 1. Possible excessive water temperature in the tube bundle. Once heater cools, high limits resets automatically. 2. Check for blockage in tubes. 3. Check for low water flow. 4. Check Unitherm governor- replace if necessary 5. check bypass assembly- replace spring or bypass if necessary |

| IGN | Ignition failure | 1. If the unit fails to hold a flame after 3 attempts, it will go into a hard lockout. Interrupt the power supply to clear the lockout and check for air in the gas line or not enough gas pressure. 2. IGN only appears after pilot has proved and main valve has been powered. |

| ILO | Ignition lockout (Propane units only) | 1. The heater has performed too many attempts to ignite the main burner and will take a short break. 2. Inspect pilot assembly. 3. If pilot assembly is OK, then the culprit may be your PC board. |

| PRS | Low water pressure | 1. Check water levels at skimmer face. (should be middle of skimmer face) 2. Ensure pump is running. 3. Check filter pressure. Backwash if necessary. 4. Check heater location- if more than 5 ft above or below water level- adjust pressure switch. |

| ROL | Thermal fuse tripped inside heater due to excessive heat or flame roll-out detected. | 1. Possible downdraft of burner flame. If sensor has red reset button, press button & determine cause. 2. Does your unit need a high wind stack? 3. Check wiring for burns- especially the ground wire and wires at gas valve. 4. Replace wires if necessary. |

| SNS | Temperature sensor is out of acceptable range. | 1. Water temperature is below 36F or above 110F 2. If the two thermistors are more than 2 degrees apart, the SNS code will appear. 3. Loose or corroded connection at P1. 4. If the sensor is not mounted all the way into the JACO fitting on the header, it may give a false reading. |

Question: Raypak Digital 406A that was on propane. But, my home underwent a natural gas conversion and I had them run a dedicated gas line which is now plumbed into the heater. I obtained Raypak’s propane-to-natural gas conversion kit per the manual which essentially swaps out the gas value regulator, burner orifices, and pilot orifice. However, since my Raypak was originally sold (to my home’s prior owner) as a propane heater, the control board has the broken tab for propane heaters. Will I need to get a new control board because that tab was broken, or if the conversion kit is installed and everything is ready for start-up and adjustments made, will I have a problem? Will the unit fault or not fire due to the control board with the broken off tab?

And a quick follow up to my prior note: If I did obtain a Raypak conversion kit for propane to natural gas, and do need a new control board that is intact without a broken tab, why on earth would Raypak’s “conversion kit” not discuss or mention the need for a new control board?

Raypak does not offer a conversion kit for Digital Electronic Ignition models 200,000btu or larger. The conversion kit is only applicable to millivolt (standing pilot) models. That being said, it’s likely that you will need a new gas valve, but you don’t necessarily have to change the PC Board. The 90-second ignition lockout, required by NFG for Propane appliances, shouldn’t have much of an impact on the operation of the heater. It may be a slight nuisance upon spring startup. It usually is not worth replacing the PC Board.

I have an electrical Raypak pool heater. I keep getting a “dsd” or “d5d” code. What could that be?

What model heater do you have? I’m not familiar with that code.

According to the manual for a Raypak heat pump, the issue is, dSd – The suction line temperature sensor is open or may be defective. You didn’t specify the actual model of your unit, so I am going with the first one I found,

Turned on my heater and was working normally. At sometime during the long day of enjoying, I went to turn off the heater and noticed a CFH code. Then after I turned the power off and turned back on, after the CFH code a CLK code comes up. Help!?

The CLK code means that the heater is off on the fireman’s switch. Is there a fireman’s switch interlocking your time clock with the heater? A fireman’s switch shuts the heater down twenty minutes before the pump shuts off. If you don’t have a fireman’s switch, check the red loop of wire, on the safety circuit connector on the PC board, for any damage or loosened connection.

When I switch on my heater is shows RV 1 then the temp .When i press the control buttons nothing happens at all???

What is the model number of your heater?

Hi – I have a 4 yr old Raypak 84 Prol model 409. The heater display says “Vent temp limit”. I reset the vent temp limit switch, checked for exhaust vent blockages (none), and increased the water flow (variable speed pump). Heater worked, then stopped within 2 hrs, displaying same message. Reset the switch again, and heater seems to work for now. What’s going on? Bad sensor? Bad switch? Bad karma?

It’s likely that the heat exchanger is sooted and needs to be pulled out and cleaned.

i have a Raypak P-R207A-EN-C that is giving a “PV output fault”. My manual and this list doesnt cover that. Is that fault a voltage issue? Are there any fuses anywhere (i dont see any)? Any help or info is greatly appreciated!

PV Output Fault typically means that either the pilot valve relay or the main valve relay on the PC board failed to open or close. Replace PC Board.

Hi! First time doing this..so here we go. I have an old Raypak 2100 pool heater – Model CR – 185 – EN. Used it extensively last summer, just tried to fire it up this year with no luck. Replaced the transformer last year, so it’s new.

I’m getting a clicking sound when I try to fire it up, so I think the electronic ignition seems to be working. No flame. The only note is that it is looking for heat (no fancy codes). I don’t smell any gas no matter how long I let it go. Your thoughts are appreciated.

If the heater is sparking, but the pilot doesn’t light, first make sure that the knob on the gas valve is turned to on, make sure the external gas shut off is set to on, and manually bleed the air from the gas line by cracking the union until you smell gas. Second, when the heater is sparking, check for 24VAC at the pilot valve terminal on the gas valve (red/black wire). If power exists at the pilot valve, loosen the pilot tube from the gas valve and see if gas comes out. If no gas, then the valve itself could be bad. If no power at the pilot valve, check for 24VAC coming from the ignition control (other end of the red and black wire). If the ignition control is sending spark, but no voltage, then it could be a faulty ignition control box.

If the pilot does light, but no main burner. First, check for 24VAC at the main valve terminal (violet/black). If the power at the main valve, but no main burner, then lightly tap the side of the gas valve. It could be stuck closed. Even if it pops open after tapping, it should be replaced. If it does not pop open, replace gas valve. If no power at main valve terminal, check for power out of the ignition control (other end of the violet/black wire). If power is coming out of ignition control, check violet and black section of wire for cuts, missing insulation, loose spade connections, etc. If no power out of ignition control, then check the green ground wire connection at the gas valve. If all ground connections are stable, then it could be a bad ignition control; but, also check the condition of the pilot itself. If it appears dirty or corroded- then remove and clean the pilot. Or, if very rusty, replace the pilot. Also, WITH THE POWER TURNED OFF, check condition of ribbon burners, by taking a piece of solid wire and running it in and out the length of all of the burners. There could be spider sacs or cobwebs interfering with the flow of gas.

Recently had my transformer replaced on my Raypak 407a heater. It then fired up and started heating. Since then, I’ve had a few issues:

1) It would shut off at random increments and the last error codes have been FAN and ROL. Not sure why it wouldn’t stay running…but it’s not a newer model that has the auto-shut off after 3 failed attempts)

2) Now, when I turn power on, it goes through its cycle but stays on SPK. I can hear it trying to spark but it never fires up. Error code now shows ROL for last several codes. When I try to press the red reset button on the rollout switch (or what I think is the rollout switch) I hear a big click and it tries to spark again. If I hold down the red reset button, the screen says ROL and SERVICE in the upper right corner.

Any ideas??

In the article, the FAN code is listed, states why it is happening, and how to fix it, same with the ROL. Have you tried any of the things mentioned in the “Possible Solutions” column?

I have a Raypack R406A heater that I inherited when I bought my home. It has worked flawlessly until recently. Beginning some time ago, it will turn on, heat the spa to around 98F then shut down. It will not re-ignite and stay on “SPK” until the power is cycled.

Is this the high limit switch? It doesn’t show any error codes, but from my research, it could be this. If so, can you tell me what part number I need and provide guidance on how to replace it?

Thanks in advance!

If you are getting SPK, and can hear the spark, then the problem is not with the high limit or any of the other safety controls. When you are seeing SPK, check to see if the pilot is lighting. If the pilot is lit, it should begin a sequence that would signal the PC board to open the main gas valve and fire the burners. Said signal is a DC signal and could be interrupted by a loose or disconnected ground wire, chewed or bare wire leading from the gas valve up to the PC board, or a loose connection at the PC board. Also, inspect the condition of the pilot itself. Excessive corrosion on the pilot could also interfere with the proving signal. If the pilot is not lit by the spark, then turn off the gas and clean the pilot and pilot tube.

Thanks for the reply. I’ll take a look at the pilot and the wiring. I did a little more testing. I can get it to light in pool mode, but it refuses to in spa mode. Installed new filters and the flow pressure is fine.

Ended up buying the current model from Inyo Pools and replaced it myself. Old unit was completely corroded. Figure it lasted 12 years, so another 12 would be amazing.

Sorry, you couldn’t salvage the old unit; but thanks for getting the new one from us.

Raypaks are pretty darn solid, you should get a good life out of it.

O have a raypak 266a. I am looking at mine and it looks like there are 2 high limit sensors, but the manual shows 1? Thanks

After reviewing a couple of Raypak diagrams, the 266A residential atmospheric heaters uses two of the Hi-Limit 135 Degree Surface Mount (006725f). The 14A picture diagram, shows the placement of the two Hi-Limit sensors as Key 6 on the headers.

So I think I understand. Since the code HL1 comes up within about 15 seconds after turning it on, it is probably a bad high limit switch? The pilot never clicks or turns on. It just says cfh for like 15 seconds, then the hl1 code. It just seems that since it isn’t even heating up, it can’t be hitting 135 f in the water. Thanks

Hi. Great site here. I have a raypack P-M266A-EP-x. I get a CFH, then an HL1(with the Service Flashing). We don’t use the heater often, but only in the hot tub once in a while. I looked up the HL1 code and it says something about the temp being too high for the high limit. The only thing is it won’t start up in the first place, so no heat is being generated.

Thank you

HL1 is a high limit trip. With the pump on, this switch should reset as the water in the header cool- the heater should fire again. If it doesn’t reset, then the hi-limit switch could be bad.

If the heater is cycling on and off on the limit switch, then it is a low water flow condition. Inspect the bypass in the header and confirm the integrity of the bypass spring. The high limit trip is telling us the water in the header is exceeding 135 degrees. Water is not moving through the exchanger fast enough causing it to super heat.

So I think I understand. Since the code HL1 comes up within about 15 seconds after turning it on, it is probably a bad high limit switch? The pilot never clicks or turns on. It just says cfh for like 15 seconds, then the hl1 code. It just seems that since it isn’t even heating up, it can’t be hitting 135 f in the water. Thanks

I have an older Raypak P-R206A-EN-C. After CFH, SPK sequence I get CLK, or sometimes heat for a minute then CLK. I do not have a clock/fireman switch.

It is clearly an failure. What is strange is that if I put pressure on or below the LCD screen, the CLK can disappear and the unit will heat? I don’t know how long because obviously I can’t stand there with my finger on the screen.

I am about to replace the control board but now I think the LCD may be creating the open?

It could be the long pin connector on the back of the board. On that connector, you will see a red loop of wire labeled fireman switch or CLK. Try wiggling that wire as the unit is calling for heat. If the heater sparks and fires, then the connection inside the plastic connector has been lost. Probably some insulation crept down the wire and interfered with the connection. Try a new section of wire harness. If that doesn’t work, it could be the pin on the board or failure inside the PC board. But try the wire first.

Getting an “ILO” error. Are there any troubleshooting tips to address this or do I just need to call a tech?

ILO is ignition lockout. If this is a propane heater, they have a 90-second lockout that is required by code. Basically, the pilot is not proving within 90 seconds. You should be able to turn the heater off and back on and it should begin the spark process again. Also, confirm that the tank has gas. If that doesn’t work, then a tech will need to look for the cause. Hope this helps.

Ok I’ll start there. Are there any detailed instructions or diagrams as to accessing the sensor and wire? I have taken off the front cover but do not know where to go from there. What is the easiest way to access the sensor and wires you think are damaged? Remove the upper panel where the digital display is? Or a side panel? Or is it in the rear? I’m fairly handy but don’t want to pull things apart that don’t need to be. Thanks!

Ok Matthew it was a lose connection at the sensor in the rear. I now have SPARK appearing on the display but it isn’t lighting. I only let it try for about 30 seconds at best. I wasn’t sure how long on initial unit startup (zero use so far, new install) it should take to fire the heater.

So I let it attempt to light for several minutes and now get the error code Ignition Failure, no pilot sensed. Gas appears to be on, could it be a low gas flow issue? Lines are new, could I possibly make an adjustment to the gas valve to allow more flow?

The sensor is located on the inlet side of the inlet/outlet header (where water enters the heater), in a white compression fitting. You will need to remove the side access panel above the inlet/outlet, then follow the wires as they lead to the main control panel. To access the control panel, the front door needs to be removed as does the two screws on each side of the control panel. The panel will then hinge down exposing the PC board. The temp sensor wires plug into the board near the bottom RH side.

Thanks for the info. See my messages above, as I have resolved the sensor issue but have a new issue. Could the gas be too low?

Hi Matthew, just installed a Raypak 156a pool heater. Getting a sensor failure code. The unit is brand new but sat in garage for a year waiting for gas line install. Was unboxed and hooked up but won’t fire. Looking for initial install startup guide or checklist. Can’t imagine what’s wrong or where to start troubleshooting.

Chances are good that a mouse got up into the heater and chewed the sensor wires.

Hello, I have a raypak p-r336a-ep-c. The unit was already installed when I bought the home and come to find out it does not work. I going the transformer was bad and not supplying voltage to the PCB. Installed a new transformer in the unit and now I have power to the PCB and the LCD backlight turns on but there is nothing displayed. Do you think i need a new PCB or just the display? Is there any way to tell if the PCB is working? Also the unit had some burned up wiring down to the ignitor that I fixed as well is this something that happens with these units. Thanks a bunch.

Most likely took out the sacrificial 5 amp fuse on the PCB- located next to the P6 terminal. This fuse protects the board from being shorted out. Its easily found at hardware or auto parts stores, or can be ordered under part #013733F.

The igniter’s high tension wire is not one that is typically able to be repaired. It could have either been melted or chewed by rodents. The high tension lead is part of the igniter #002003F and should be replaced. I would also inspect all other wiring in the unit prior to replacing the 5 amp fuse and powering up the heater.

Thank you for the reply. The fuse is not blown and there is no other damage with the wiring that hasn’t been fixed. The LCD backlight lights up but there is no actual display. Is there any way to determine if the LCD is just not working and the PCB is? Thanks again.

Okay, good. Could be just the display, but the heater should work. Problem is that, without the display, we don’t know what mode we are in and where the set points are. Try and press the mode button once and press the red up button a few times. If you hear a click and a spark, then the display is bad and the PCB is good. The display is replaceable, by removing the PCB and squeezing the two tabs on the back that hold the display to the board. If indeed this is the case, I can have one sent to you.

I have Raypac C-R406A-EN-C. When it turns on it calls for heat, says spark, the pilot lights, then opens gas for the burner and burns for 3 seconds says heating, the burner turns off then calls for spark again. This continues cycling off and on, yet is does not stay burning. I have checked all sensors and none are bad. Help please.

Sounds fuel related. If a spring start, could be air in the line. If so, should bleed out. Is there a vent tied into the heater?

We are connected to natural gas, flame looks good when it does burn. It is indoor and has a vent.

Is there a power vent or extractor interlocked with the heater?

I work at a rental property and they have a pool&spa area. I have two ray pac units that are giving me problems they both go into pro5 codes and say clean both pumps straners and i take them out and clean them which they both have nothing in restart them both they light and run for 2 minutes they both shut down and relight again but they both go into pro5 codes saying clean straners again but nothing in them . What can i do.

What is the model number of the heater? The residential models only flash 3-letter codes. Do you mean it was a PRS (pressure switch open)? If so, thoroughly backwash or clean the filter; if that doesn’t work then you’ll likely have to replace pressure switch.

Hello Matthew!

We have a Raypak M336A, and the tech came out on Monday to turn the pool on for the season. He checked the heater and it fired up right right away. But now it won’t ignite, it just sparks. It’s throwing the HL1 and GVO codes. Any help would be appreciated, Thanks!

Andres, those codes and what are causing them are listed in the article. Have a tech come out to correct the issue if you do not think you can check the systems that are mentioned in the recommended actions.

Hi Matthew

i have just purchased a new raypak M206A Pool heater and i shipped it to Thailand.

Can you tell me what the input gas normal operating pressure should be.

Thanks

Did the manual ship with the unit? Is it Propane or Natural Gas?

i have a raypak tankless and when i run water it flashes 11 and beeps when my temp should be 120 any ideas whats wrong here?

Is this Raypak unit you are working on a pool heater or a tankless water heater? I can help you with the pool heater, but I would need to know the model number of the pool heater.

If you are referencing a house water heater, you would have to contact Raypak or a boiler technician company.

I fogot to add – I”ve backwashed it, pressure is good. Haven’t changed anything to the hardware.

Hi

I”ve got a RP2100, it’s worked fine for about 10 years, in the last week it will only heat up to about 85 deg. I’ve got the temp set for 102. It turns on fine SPK comes on and ignites runs with no error codes after about 15 minutes it will show SPK on display and reignite and run for about 10 more minutes then it repeats that and only gets to about 80some degrees. where should I look for the problem, no error codes.

One of our close Raypak techs said to check for any loose wires/crimps in the wire harness. Also, check the wired going into the connector that plugs into the PC Board. Sounds as if it could be momentarily losing contact.

Rheem natural gas pool heater model P-M267AEN-C throwing code PR5 and message “CLEAN FILTER STRAINER” with “Service” in smaller letters on top right hand side of display. According to your code reference it may be a clogged pool filter needing backwash. Are there any filters inside the heater I also need to pay attention to?

Thank you.

The heater does not have filters that need cleaning. The PRS code is referring to low water pressure. If your pump strainer is clogged or your filter media is dirty, the water flow could lower below the heater’s minimum water requirement. If you have a variable speed pump, sometimes this will flash if your pump drops to lower RPMs.